Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

Inquiry now

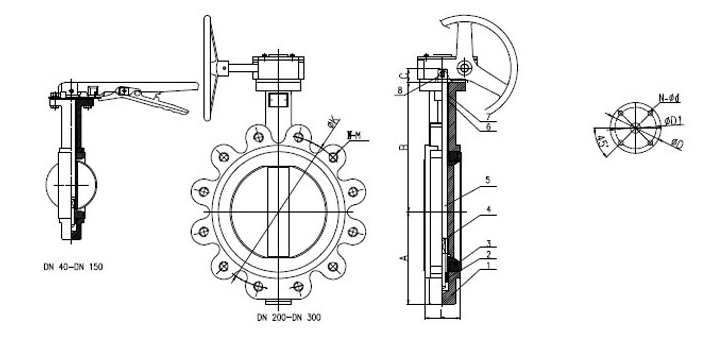

Size Range: 2~24"(DN50~DN600)

Pressure: PN10, PN16, Class150

Seat Materials: NBR, EPDM, VITON, PTFE

Disc Materials: Ductile Iron, WCB, CF8,CF8M, Al-bronze C958

Stem Materials: SS304, SS316

End Connection: wafer

Operate: Manual, Worm gear, Pneumatic, Electric-Motorized

Disc type: With-pin

In several common connection ways of butterfly valves, the price of wafer type is the cheapest, followed by lug type butterfly valve, flange type butterfly valve is the most expensive, the price is proportional to the overall weight. In the relevant standard, it is not clear whether the pressure hole of the lug type is a through hole or a threaded hole, so both on the market can be seen.

1. For through hole lug type butterfly valve,it is installed in the same way as the wafer type butterfly valve, so its stability is not as good as flange type one.

2. For threaded hole lug style butterfly valves, its installation way is different with the wafer type and the flange type, at this time the lug type butterfly valve’s holes are like nuts ,when connecting with the pipe flange, the bolts passes through the flange, the holes of the lug type butterfly valve are tightened directly with the bolts.

This installation is stable ,even better than flange types.The lug type body has one integral flange with an identical hole pattern to the pipe flanges. Each hole is tapped from opposite direction, meeting in the center of the hole. This style allows the body to be placed between two flanges. A stud bolt can be inserted through the piping flange and threaded into the integral flange with a nut to secure the entire flange connection.The lug style designs are mainly used in thermal expansion applications in which the risks of straight-through bolting can't be taken while small size designs can't permit two integral flanges.

There are several ways to actuate a butterfly valve:

Manual operation, Pneumatic actuation, Electric actuation, Hydraulic actuation etc.,

The most commonly used is the manual operation type.

What is a manual butterfly valve?

A manual butterfly valve is a type of valve that is operated manually by turning a handle or handwheel to control the flow of liquids or gases in a pipeline. It consists of a disc or plate that is mounted on a rotating shaft, which is positioned perpendicular to the flow direction. When the handle or handwheel is turned, the disc rotates to either fully open or fully close the valve.

Manual Butterfly valves are widely utilized across industries including water treatment, chemical processing, and food and beverage systems due to their uncomplicated design, user-friendly operation, and dependable functionality. These valves are suitable for both on/off and throttling applications, making them versatile and cost-effective solutions for flow control needs.

Features

vertical center line disc

Anti-Blow Out Stem

Bi-Directional

Fire safe Design

Low Friction Body Seat

Zero Leakage

Standard Test

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

Application

1.Water Treatment Plant

2.Breweries

3.Drilling Rigs

4. Heating & Air Conditioning

5.Paper Industry

6.Chemical Industry

7.Gas Plant

8.Pneumatic Conveyors

9.Sugar Industry

10.Waste Effluent Treatment Plant

11.Cooling Water Circulation

12.Compressed Air

Dimensions (DIN / ASME)

| SIZE | HA | HB | HC | L | Φ A | DIN PN16 | ASME B16.1 | |||

| DN | INCH | Φ C | n - M | Φ C | n - M | |||||

| 50 | 2" | 66 | 130 | 30 | 43 | 12.7 | 125 | 4-M16 | 129.5 | 4-5/8" |

| 65 | 2-1/2" | 75 | 140 | 30 | 46 | 12.7 | 145 | 4-M16 | 139.5 | 4-5/8" |

| 80 | 3" | 95 | 150 | 30 | 46 | 12.7 | 160 | 8-M16 | 152.5 | 4-5/8" |

| 100 | 4" | 108 | 170 | 30 | 52 | 15.8 | 180 | 8-M16 | 190.5 | 8-5/8" |

| 125 | 5" | 120 | 185 | 30 | 56 | 19.1 | 210 | 8-M16 | 216.0 | 8-3/4" |

| 150 | 6" | 134 | 205 | 30 | 56 | 19.1 | 240 | 8-M20 | 241.5 | 8-3/4" |

| 200 | 8" | 168 | 235 | 36 | 60 | 22.2 | 295 | 12-M20 | 298.5 | 8-3/4" |

| 250 | 10" | 200 | 270 | 36 | 68 | 28.6 | 355 | 12-M24 | 362.0 | 12-7/8" |

| 300 | 12" | 237 | 305 | 36 | 78 | 31.8 | 410 | 12-M24 | 432.0 | 12-7/8" |

| 350 | 14" | 262 | 330 | 36 | 78 | 31.8 | 470 | 16-M24 | 476.0 | 12-1" |

| 400 | 16" | 300 | 360 | 51 | 102 | 33.3 | 525 | 16-M27 | 539.5 | 16-1" |

| 450 | 18" | 350 | 395 | 51 | 114 | 38.0 | 585 | 20-M27 | 578.0 | 16-1-1/8" |

| 500 | 20" | 375 | 440 | 64 | 127 | 41.2 | 650 | 20-M30 | 635.0 | 20-1-1/8" |

| 600 | 24" | 435 | 500 | 71 | 154 | 50.7 | 770 | 20-M33 | 749.5 | 20-1-1/4" |

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve