Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

Inquiry now

Types: Dismantling Joint, Universal Flange Adaptor, Universal Coupling, Ductile Iron Loose Flange Joint, DI Pipe Fitting, Saddle for PVC Pipe, Repair Clamp, Qucick Flange Adaptor, Gibault Joint, Restrained Flange Adaptor, Restrained Coupling, Valve, etc.

Material: MATERIAL: Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083 for ductile iron fitting body and retainer, EPDM/NBR for ring, steel zinced/dacro for stub.

|  |

Specification: DN50-DN2000(2"-80"), available with PN10, PN16, PN25 and PN40 flanges

Ductile Iron Flange Fittings Standard: ISO2531, ISO4179, ISO8179, BS EN 545, BS EN598, BS4772, ISO7005-2, EN1092-2:1997, DIN2501, GBT13295

Flange: PN10, PN16 or PN25 drilling in accordance with ISO 7005-2/EN 1092-2.

Fluid Temperature: 0°C-50°C, excluding frost.

Pipe ends: Spigot, socket or flanges.

Internal coating: Cement mortar lining comply with ISO4179 or bitumen painting (Ave. min.70 micron) or Fusion Bonded Epoxy Coating

External coating: Sprayed metallic zinc coating (min.150g/m²) according to ISO8179 + bitumen painting (min.70 micron) or epoxy powder coating or epoxy painting or according to customer’s requirements.

Types: Dismantling Joint, Universal Flange Adaptor, Universal Coupling, Ductile Iron Loose Flange Joint, DI Pipe Fitting, Saddle for PVC Pipe, Repair Clamp, Qucick Flange Adaptor, Gibault Joint, Restrained Flange Adaptor, Restrained Coupling, Valve, etc.

Material: MATERIAL: Ductile iron grade 500-7/ 450-12 in accordance with ISO 1083 for ductile iron fitting body and retainer, EPDM/NBR for ring, steel zinced/dacro for stub.

Application: Municipal Use, Waterworks Pipelines, Piping Fittings, Water Engineering, Potable Water Use, Irrigation Use, Water Supply Project Use, Water Treatment Plants Use, Pumping Stations, Water Utility Sectors, Water-Supply Pressure Pipeline, Potable Water Pumping Station, Stormwater Lines, Fire Water Pumping Station, Fresh Water Pumping Station, ect.

Test: In accordance with ISO 2531 / EN 545 / EN598 and 100% water pressure test.

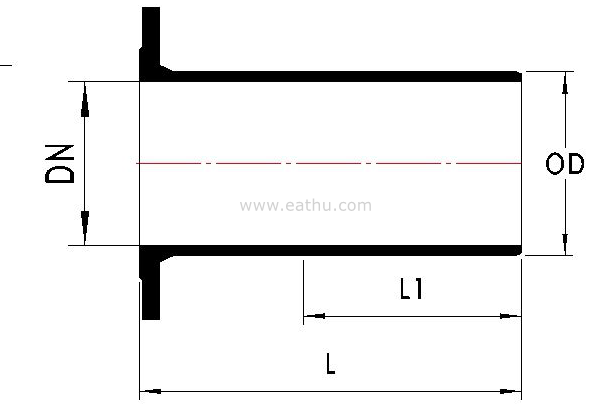

A flanged spigot is a type of fitting used in piping systems. It features a flange on one end, which allows it to be bolted or connected to another component, such as a flange on a pipe or a valve. The spigot end is usually designed to fit into another pipe or fitting, creating a secure and leak-proof connection.

Key Characteristics:

1. Flanged Connection: The flange provides a large surface area for sealing and securing the connection, often using bolts and a gasket to prevent leaks.

2. Spigot End: The spigot end is typically tapered or straight and is designed to fit into a corresponding socket or fitting.

3. Material: Flanged spigots can be made from various materials, including PVC, ductile iron, stainless steel, and others, depending on the application and the medium being transported.

4. Applications: Commonly used in water supply systems, wastewater treatment, and industrial processes where secure and reliable connections are essential.

5. Installation: Flanged connections require proper alignment and tightening of bolts to ensure a leak-free joint, often requiring a torque wrench to achieve the correct tension.

Advantages:

- Ease of Maintenance: Flanged connections can be easily disassembled for maintenance or replacement of components.

- Versatility: They can be used in a variety of applications and environments, accommodating different pressures and temperatures.

- Strong Connection: The design provides a robust and reliable joint that can handle significant mechanical stress.

Considerations:

- Alignment: Proper alignment of the flanges is critical during installation to avoid undue stress on the piping system.

- Gasket Selection: The right gasket material must be chosen based on the fluid being transported and the operating conditions to ensure a seal.

- Corrosion Resistance: In corrosive environments, selecting the appropriate material for the spigot and flange is essential to ensure longevity and performance.

In summary, flanged spigots are integral components in many piping systems, offering secure connections and facilitating easy maintenance.

Dimensions of Flanged Spigot

| DN | L | Mass (kg) | standard | |||

| PN10 | PN16 | PN25 | PN40 | |||

| 40 | 335 | 4.2 | 4.2 | 4.2 | 4.2 | ISO2531/EN545 |

| 50 | 250 | 4.4 | 4.4 | 4.4 | 4.4 | |

| 340 | 5.2 | 5.2 | 5.2 | 5.2 | ISO2531/EN545 | |

| 500 | 6.7 | 6.7 | 6.7 | 6.7 | ||

| 600 | 7.6 | 7.6 | 7.6 | 7.6 | ||

| 1000 | 11.5 | 11.5 | 11.5 | 11.5 | ||

| 60 | 345 | 5.8 | 5.8 | 5.8 | 5.8 | ISO2531/EN545 |

| 65 | 345 | 6.5 | 6.5 | 6.4 | 6.4 | ISO2531/EN545 |

| 80 | 250 | 6.4 | 6.4 | 6.4 | 6.4 | |

| 350 | 7.8 | 7.8 | 7.8 | 7.8 | ISO2531/EN545 | |

| 400 | 8.8 | 8.8 | 8.8 | 8.8 | ||

| 500 | 10 | 10 | 10 | 10 | ||

| 600 | 11.5 | 11.5 | 11.5 | 11.5 | ||

| 1000 | 17 | 17 | 17 | 17 | ||

| 1200 | 20 | 20 | 20 | 20 | ||

| 100 | 360 | 9.6 | 9.6 | 10.2 | 10.2 | ISO2531/EN545 |

| 400 | 10.6 | 10.6 | 11.2 | 11.2 | ||

| 500 | 13.5 | 13.5 | 14.1 | 14.1 | ||

| 700 | 17 | 17 | ||||

| 1000 | 21 | 21 | 21.5 | 21.5 | ||

| 125 | 370 | 12.4 | 12.4 | 13 | 14.3 | ISO2531/EN545 |

| 400 | 14 | 14 | 14.6 | 15.9 | ||

| 1000 | 29.5 | 29.5 | ||||

| 150 | 380 | 15.6 | 15.6 | 16.6 | 18.7 | ISO2531/EN545 |

| 406 | 19.5 | 19.5 | 20.5 | 22.6 | ||

| 500 | 19 | 19 | ||||

| 750 | 26.5 | 26.5 | 27.5 | 29.6 | ||

| 1000 | 33 | 33 | 34 | 36.1 | ||

| 200 | 150 | 13 | 12.6 | 14.7 | 20 | |

| 400 | 22.9 | 22.5 | 24.5 | 30 | ISO2531/EN545 | |

| 406 | 25.4 | 25 | 27.1 | 32.5 | ||

| 500 | 27 | 27.6 | ||||

| 600 | 30.6 | 30.4 | 32.5 | 40 | ||

| 1000 | 46.5 | 46.3 | 48.4 | 54 | ||

| 1200 | 54.4 | 54.2 | 56.3 | 61.5 | ||

| 250 | 406 | 36.8 | 36 | 40 | 50.1 | |

| 420 | 32.3 | 31.5 | 35.5 | 45.5 | ISO2531/EN545 | |

| 500 | 36.5 | 35.7 | ||||

| 1000 | 62.8 | 62 | 66 | 76.1 | ||

| 1500 | 89.2 | 88.4 | 92.5 | 102.6 | ||

| 300 | 300 | 33.4 | 32.6 | 38.2 | 44 | |

| 406 | 48.3 | 47.5 | 53 | 58.5 | ||

| 440 | 43.3 | 42.5 | 47.5 | 63 | ISO2531/EN545 | |

| 500 | 47.4 | 46.6 | ||||

| 700 | 60.3 | 46.6 | 65.2 | 71 | ||

| 1000 | 80.5 | 79.7 | 85.2 | 91 | ||

| 1200 | 93.9 | 93.1 | 99 | 104.5 | ||

| 1500 | 114.3 | 113.5 | 119.2 | 124.7 | ||

| 350 | 460 | 49 | 55 | 64 | ISO2531/EN545 | |

| 1000 | 94.2 | 100.2 | 108.5 | |||

| 1200 | 111 | 117 | 125.5 | |||

| 400 | 480 | 59 | 70 | 81 | ISO2531/EN545 | |

| 1000 | 119 | 124.6 | ||||

| 450 | 500 | 70 | 87 | 98 | ISO2531/EN545 | |

| 1000 | 129.5 | 146.5 | ISO2531/EN545 | |||

| 500 | 520 | 79 | 109 | 121 | ISO2531/EN545 | |

| 495 | 75.7 | 105.7 | 117.5 | |||

| 1000 | 163.6 | 178.8 | ||||

| 600 | 560 | 112 | 159 | 173 | ISO2531/EN545 | |

| 1000 | 217 | 243.5 | ||||

| 700 | 600 | 164 | 194 | ISO2531/EN545 | ||

| 800 | 600 | 226 | 245 | ISO2531/EN545 | ||

| 900 | 600 | 272 | 295 | ISO2531/EN545 | ||

| 1000 | 600 | 328 | 369 | ISO2531/EN545 | ||

| 1100 | 600 | 394 | 430 | ISO2531/EN545 | ||

| 1200 | 600 | 456 | 520 | ISO2531/EN545 | ||

| 1400 | 710 | 664 | 732 | ISO2531/EN545 | ||

| 1500 | 750 | 812 | 900 | ISO2531/EN545 | ||

| 1600 | 780 | 922 | 1024 | ISO2531/EN545 | ||

| 1800 | 850 | 1196 | 1322 | ISO2531/EN545 | ||

| 2000 | 920 | 1534 | 1687 | ISO2531/EN545 | ||

| 2200 | 990 | 1948 | 2115 | ISO2531 | ||

| 2400 | 1060 | 2409 | 2611 | ISO2531 | ||

| 2600 | 1130 | 2918 | 3153 | ISO2531 | ||

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve