Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

Inquiry now

Flanges are integral components in piping systems, serving as the connective elements that join pipes, valves, pumps, and other equipment to form a complete system. They provide the necessary access points for maintenance, inspection, and repairs, enhancing the reliability and functionality of the piping infrastructure.

As a leading manufacturer and exporter specialized in steel valves, fittings, pipe couplings and flanges, FLUIDO has been serving 35+ countries/regions for over 20 years. In addition to manufacturing its own flanges, FLUIDO also established partnership with factories in Shandong and Hebei, so as to provide customers with a full range of products and one-stop sourcing services.

Importance of Flanges in Piping

Flanges play a crucial role in ensuring the seamless operation of piping systems. Their importance can be highlighted through:

Seamless Connection: They provide a secure and leak-proof connection, essential for the safe transport of fluids and gases.

Maintenance and Inspection: Flanges enable straightforward disassembly for maintenance and inspection, which is vital for ongoing system reliability.

Flexibility: They offer flexibility in system design, allowing the integration of various components without extensive welding or threading.

Safety: Properly installed flanges ensure system safety by maintaining the integrity of joints and preventing leaks that could lead to hazardous conditions.

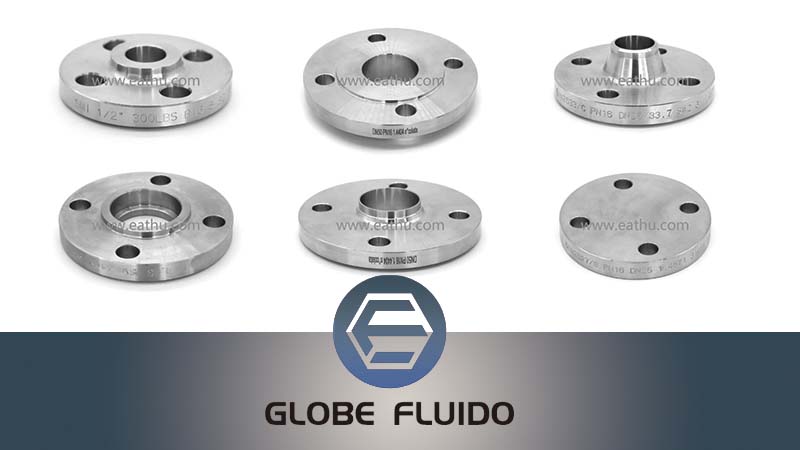

Common Types of Flanges

Several types of flanges are commonly used in piping systems, each serving specific purposes based on their unique design and application:

Weld Neck Flanges: Known for their robustness and strength, these flanges are used in high-pressure and high-temperature applications.

Socket Weld Flanges: Ideal for smaller pipe diameters, they are commonly used in low-pressure applications.

Slip-On Flanges: Easy to install and suitable for low-pressure conditions, particularly in situations where space is constrained.

Blind Flanges: Used to seal the ends of piping systems, effectively preventing flow.

Lap Joint Flanges: Often used in conjunction with stub ends, they are prevalent in systems requiring frequent dismantling.

Introduction to Socket Weld Flanges

Definition and Description

Socket weld flanges are a type of pipe flange that involves inserting the pipe into a recessed area of the flange before welding it in place. This design ensures a precise alignment and a strong connection, particularly in systems with smaller pipe diameters.

Applications and Uses

Socket weld flanges are commonly employed in industries where small-diameter piping systems are prevalent:

Chemical Processing: They are used in systems that require high pressure and temperature resistance.

Oil and Gas: Ideal for various processing applications due to their robust nature.

Pharmaceutical: Used in cleanroom environments for their easy installation and strong seals.

Power Generation: Integral to systems requiring high strength and reliability.

Advantages of Socket Weld Flanges

Socket weld flanges offer several advantages that make them suitable for specific applications:

Strong Connection: They provide a secure and leak-proof joint, which is crucial in high-pressure applications.

Ease of Installation: The socket design simplifies alignment and installation, saving time and labor costs.

Durability: Known for their durability, they are well-suited for systems exposed to cyclical stress and vibration.

Cost-Effectiveness: Generally, socket weld flanges are more cost-effective than other types, making them a preferred choice for budget-conscious projects.

Introduction to Weld Neck Flanges

Definition and Description

Weld neck flanges are distinguished by their long, tapered hub, which gradually transitions to the thickness of the pipe. This design contributes to their ability to withstand high-pressure and high-temperature conditions, making them a staple in demanding environments.

Applications and Uses

The robust nature of weld neck flanges means they are employed in various critical applications:

Petrochemical: Used extensively in high-temperature and high-pressure systems.

Marine: Essential in shipbuilding and offshore oil platforms due to their strength and resistance to harsh environments.

Nuclear Power: Employed in systems that require utmost reliability and safety.

Aerospace: Used where both critical performance and strength are necessary.

Advantages of Weld Neck Flanges

Weld neck flanges bring several key benefits that enhance their suitability for demanding applications:

Strength and Durability: Their design ensures they can bear substantial loads and endure significant stress.

Leak-Proof Connection: They provide a superior seal, reducing the risk of leaks and enhancing system safety.

Resistance to Conditions: They excel in high-pressure, high-temperature, and corrosive environments, providing long-term reliability.

Alignment and Support: The tapered hub aids in the proper alignment of the pipeline, reducing the risk of issues during installation.

By understanding these flanges in detail, one can make informed decisions on which type to select for specific applications, ensuring optimal performance and longevity of piping systems.

Key Differences Between Socket Weld Flanges and Weld Neck Flanges

Design Differences

The primary design difference between socket weld flanges and weld neck flanges lies in their structural characteristics. Socket weld flanges feature a socket or recessed area where the pipe is inserted before welding, creating a fillet weld around the joint. This design yields strong connections for smaller diameter pipes. In contrast, weld neck flanges have a long, tapered hub that gradually transitions to the pipe's thickness, allowing for butt welding to the end of the pipe. This design provides superior strength and durability, making weld neck flanges more suitable for high-pressure and high-temperature applications.

Installation Process

The installation process for these flanges also varies significantly. Socket weld flanges require the pipe to be socketed into the flange and then welded around the joint, which simplifies the alignment and welding process since the pipe is securely held in place during installation. On the other hand, weld neck flanges involve butt welding, which demands precise alignment and often more extensive welding expertise. This process can be more labor-intensive and time-consuming, but it results in a stronger, more resilient joint, particularly beneficial in high-stress environments.

Performance Considerations

From a performance standpoint, weld neck flanges generally offer superior resistance to environmental stress and pipe loading due to their tapered hub and the butt welding process. This design reduces the risk of disjointing under pressure, making weld neck flanges ideal for critical systems where failure is not an option. Socket weld flanges, while strong and leak-proof, are typically better suited for applications involving lower pressures and smaller pipe diameters. Their design and installation process make them less capable of handling the high-stress conditions where weld neck flanges excel.

When to Use Butt Weld Flange Instead

Butt Weld Flange Overview

Butt weld flanges are integral in forming a strong, continuous, and seamless piping network. Characterized by the process where the pipe and flange are beveled and joined by a complete penetration weld, these flanges ensure the highest level of joint integrity. Butt weld flanges are highly valued in applications that cannot tolerate leaks or joint failures, offering a robust and durable connection.

Appropriate Scenarios for Butt Weld Flange Use

Butt weld flanges are particularly useful in scenarios demanding high structural integrity and minimal leakage. These include high-pressure applications where a seamless connection is necessary to prevent the escape of potentially hazardous fluids or gases. They are also favored in high-temperature environments, where thermal expansion and contraction could compromise the integrity of other flange types. Industries such as oil and gas, petrochemical, and power generation often utilize butt weld flanges due to their durability and reliability under extreme conditions.

All products undergo thorough inspection prior to shipment. FLUIDO is proud to be certified under the international ISO9001 quality management standard, ensuring adherence to stringent quality criteria and industry norms. Upholding our belief that "trust originates from quality," we have successfully achieved ISO9001 certification along with SGS quality management registration. Moreover, our valve and flange products carry European CE certification.

Practical Recommendations for Selection

Factors to Consider in Choosing the Right Flange Type

Selecting the appropriate flange type requires considering several factors:

System Pressure and Temperature: High-pressure or high-temperature systems generally benefit from the strength and durability of weld neck or butt weld flanges.

Pipe Size and Diameter: Smaller diameter pipes often find socket weld flanges more suitable due to the ease of alignment and installation.

Environmental Conditions: For environments with corrosive materials or extreme conditions, the material and robustness of weld neck and butt weld flanges are advantageous.

Ease of Maintenance and Inspection: Flanges that are easier to disassemble and reassemble can reduce downtime and maintenance costs, a critical factor in industries requiring frequent inspections.

Cost Implications and Budgeting Concerns

Cost is a critical consideration when selecting flanges. Socket weld flanges are generally more cost-effective due to their simpler installation process and suitability for lower-pressure applications. Weld neck and butt weld flanges, while more expensive and labor-intensive to install, offer superior performance and reliability, translating into long-term savings through reduced maintenance and downtime. When budgeting, it's important to balance initial installation costs with the long-term operational savings and reliability provided by the more robust flange types.

In conclusion, understanding the differences between socket weld, weld neck, and butt weld flanges, along with their specific applications, is crucial for making informed decisions that ensure the safety, reliability, and efficiency of piping systems.

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve