What should I consider before purchasing flanges?

Qingdao Fluido Industrial Co.,Ltd

When you purchase flanges, you should have several concerns or considerations in mind. Some of the key factors that you should concerned about include:

1. Flange Material: You should prioritize specific materials such as carbon steel, stainless steel, or alloys based on your desired properties like strength, corrosion resistance, temperature resistance, or compatibility with the fluid or gas being transported.

2. Flange Size and Dimensions: You need to ensure that the flanges you purchase are of the correct size and dimensions to fit your specific application. This involves considering factors like flange diameter, bolt hole size and spacing, flange thickness, and overall dimensions to ensure proper installation and compatibility with the piping system.

3. Pressure and Temperature Ratings: You should concern about the pressure and temperature ratings of the flanges you purchase. You need to ensure that the flanges can withstand the expected pressure and temperature conditions in their specific application without any leaks, failures, or safety hazards.

4. Flange Type and Standard: You should have specific requirements regarding the type of flange you need, such as slip-on, weld neck, threaded, socket weld, or blind flanges. You also should consider the relevant industry standards, such as ANSI, ASME, DIN, or JIS, to ensure compliance, compatibility, and interchangeability.

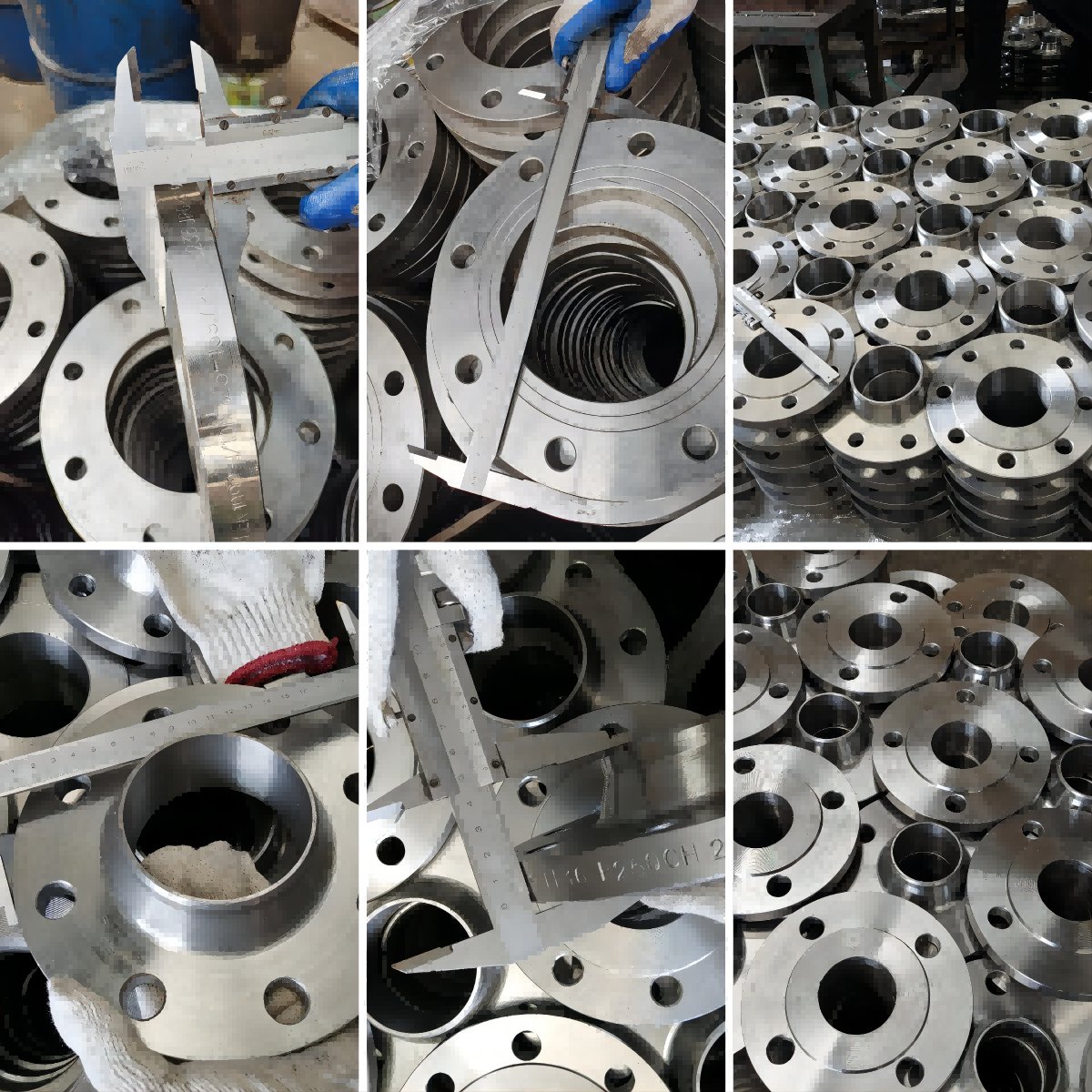

5. Quality and Reliability: You should concern about the quality and reliability of the flanges you purchase. You should look for flanges from reputable manufacturers or suppliers known for producing high-quality products that meet industry standards and undergo proper testing and inspections. Qingdao Fluido is a good choice who has been in this field for over 20 years. Check the information from: https://www.eathu.com/product/fluido-flange.html

6. Pricing and Cost: You should consider the pricing and overall cost of the flanges, including factors like the initial purchase cost, any additional expenses for installation or modifications, and the long-term maintenance and operational costs associated with the flanges.

7. Supplier Reputation and Support: you should be concerned about the reputation and reliability of the supplier or manufacturer from whom you purchase the flanges. You should look for suppliers with a track record of delivering on time, providing technical support, offering warranty or after-sales service, and maintaining good customer relationships.

8. Certifications and Compliance: You may should require flanges that meet specific certifications or compliance requirements, such as ISO, API, ASTM, or NACE standards. You should also have specific industry-specific regulations or codes to adhere to, such as those in the oil and gas, chemical, or power sectors.