Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

Inquiry now

As the global focus on combating climate change intensifies, the European Union (EU) has implemented the Carbon Border Adjustment Mechanism (CBAM). CBAM aims to reduce the risk of “carbon leakage,” which occurs when businesses relocate their manufacturing operations to nations with environmental regulations to avoid costs related to their carbon emissions. By imposing a carbon tax on goods imported from countries, outside the EU region the EU aims to encourage production practices across the supply chain.

For the suppliers exporting products like steel, aluminum and metal components to the European market, CBAM represents both a challenge and an opportunity. Though meeting CBAMs paperwork demands may appear daunting it also offers these suppliers the chance to showcase their dedication to sustainability. Qingdao Fluido is a provider of flanges and pipe fittings that has actively worked towards ensuring their products adhere, to CBAM requirements. This article delves into the criteria, for CBAM. Offers suggestions from Qingdao Fluido, on how suppliers could adhere to these fresh guidelines effectively.

When businesses move their production to countries, with carbon emission regulations to avoid carbon taxes but still release a lot of greenhouse gases into the atmosphere. That's what we call carbon leakage. To tackle this problem and make things fair for companies while encouraging suppliers to cut down on emissions too. The Carbon Border Adjustment Mechanism (CBAM) steps in by placing a tax on imported goods. CBAM is starting by focusing on industries like steel making and chemical production that have an impact on our environment, with their levels of carbon emissions.

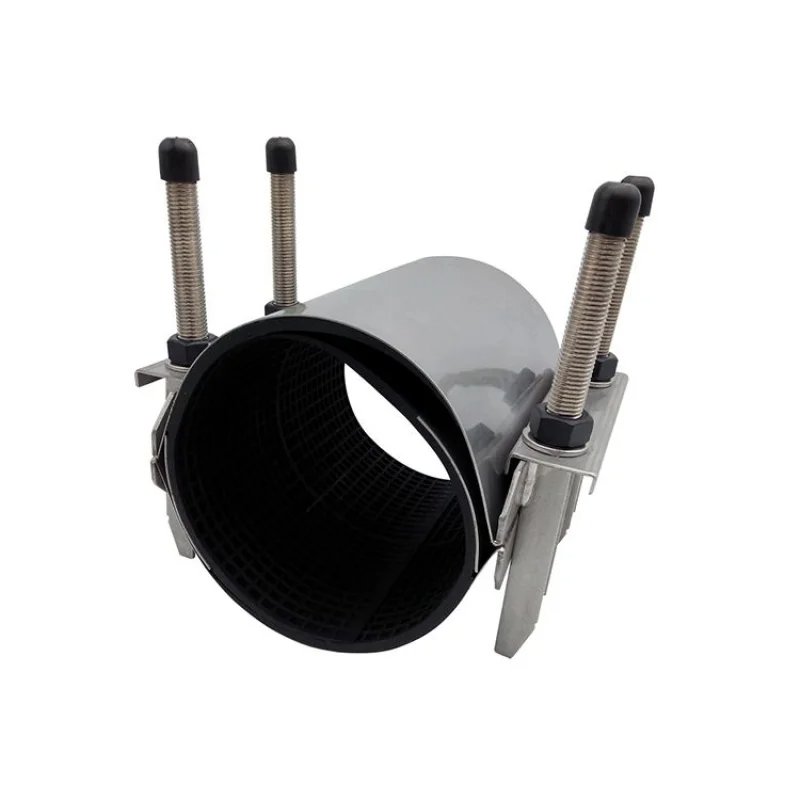

Industries like steel production, pipe fittings, and flanges are among those heavily impacted by CBAM because of the energy methods used in their production processes. Suppliers, within these industries are now required to evaluate and disclose the carbon emissions linked to their goods to prevent encountering import duties when shipping to Europe.

To comply with CBAM regulations suppliers must provide documentation that details the carbon footprint of their merchandise. This data is crucial, for determining the carbon levy imposed on imported goods destined for Europe. Suppliers who fail to meet these requirements could jeopardize their presence in the market. Encounter higher tariffs that diminish the competitiveness of their products. Therefore, understanding the documentation process and ensuring accuracy is critical for suppliers looking to continue exporting to the EU.

The carbon footprint report plays a role, in meeting CBAM regulations as it evaluates the greenhouse gas emissions produced during the manufacturing of a product, including both direct emissions from production activities and indirect emissions from energy uses. Suppliers are responsible, for ensuring the report is accurate and encompasses all stages of production.

Energy usage data plays a vital role in CBAM documentation. Suppliers must provide detailed records of the types and amounts of energy used in their manufacturing processes. This information helps calculate the total carbon emissions for each product. Switching to cleaner energy sources can significantly reduce the carbon footprint, which is something suppliers should consider to meet CBAM requirements.

Life Cycle Assessment (LCA) is used to assess how a product impacts the environment from the extraction of materials to its disposal at the end of its life cycle. It's important to conduct an LCA to pinpoint emission sources and find ways to make improvements. Suppliers need to perform LCAs, for all their products to accurately report carbon emissions under CBAM.

When suppliers participate in carbon offset projects, for CBAM documentation requirements they need to submit carbon offset certificates to demonstrate their efforts, in neutralizing their carbon emissions by supporting initiatives that lower or capture carbon dioxide levels The certificates serve as proof that a business is committed to reducing its footprint by investing in projects Although offsets alone may not eliminate the requirement to reduce emissions at the root source they play a crucial role in lessening the ecological consequences of manufacturing processes.

Qingdao Fluido is a leading company that specializes in producing flanges and pipe fittings along, with metal parts and has gained significant expertise in the European market over time. With the introduction of CBAM regulations, the company has taken steps to guarantee that its products adhere to the standards set by the EU. Qingdao Fluido's wealth of knowledge and skills position them as a reliable source for suppliers looking for advice on ensuring compliance, with CBAM requirements.

To help other suppliers navigate the complexities of CBAM, Qingdao Fluido has developed four key recommendations that streamline the compliance process and ensure accurate carbon reporting.

Identifying Major Emission Sources in Production

One of the biggest challenges for suppliers is accurately identifying where emissions are generated during production. The suppliers need to start by pinpointing major emission sources such as energy consumption in machinery, raw material transportation and waste management.

Using Digital Tools to Track Carbon Data

To simplify the process of carbon footprint calculation, Qingdao Fluido uses digital tools that automate the collection of emissions data across their entire supply chain. This allows them to monitor energy usage in real time and ensure that carbon data is precise and up-to-date.

The Role of Energy Providers in CBAM Compliance

Energy consumption is a major contributor to carbon emissions in metal manufacturing. Suppliers can partner with energy providers that offer renewable energy solutions to reduce the carbon footprint of production processes.

Recommended Clean Energy Choices for Suppliers

To fulfill CBAM requirements effectively as a supplier consider signing contracts with energy providers that prioritize sustainability. Opting for sources, like power, wind energy, or hydropower can aid in cutting down carbon emissions and lessening the reliance on costly carbon offsets.

Conducting a Comprehensive LCA

The suppliers can adopt a perspective when carrying out Life Cycle Assessments by encompassing their product life cycle—starting from the extraction of raw materials to the disposal phase—in the evaluation process.

Reducing Emissions Through Material and Transportation Optimization

Two tactics for emissions; maximizing raw material utilization and enhancing transportation logistics efficiency through the adoption of eco-friendly materials and optimized shipping routes.

Staff Training on Carbon Management and CBAM Documentation

The staff training is very important to ensure that employees understand CBAM documentation requirements and are familiar with carbon management practices.

Collaborating with Industry Associations for Compliance Updates

The suppliers can stay informed on the latest CBAM guidelines by collaborating with industry associations and environmental organizations. This ensures they are always up to date with the evolving regulatory landscape.

Failure to comply with CBAM can lead to significant financial penalties and the potential loss of access to the European market. Suppliers must prioritize accurate documentation to avoid these risks.

Suppliers who adopt CBAM compliance measures do not just safeguard their market entry. It also bolsters their image as conscientious enterprises. Qingdao Fluidos approaches provide a framework, for sustaining competitiveness in the eco-European market.

CBAM plays a role in the EU plan to lower carbon emissions and promote sustainable business methods, showing that suppliers adhering to CBAM are playing their part in the global fight against climate change.

Qingdao Fluido recommends that suppliers address CBAM compliance challenges through four key measures: First, simplify carbon footprint calculations, identify major emission sources, and use digital tools to monitor data in real time. Second, work with renewable energy suppliers to select sustainable energy solutions to reduce carbon emissions in production. Third, conduct a comprehensive life cycle assessment to optimize raw material utilization and transportation efficiency to reduce emissions. Finally, regularly train employees to ensure understanding of CBAM requirements, and stay tuned to the latest regulations through collaboration with industry associations.

If you are a European importer of flanges and pipe fittings and are troubled by the fact that your supplier cannot provide CBAM forms, please contact Qingdao Fluido. We are a very experienced supplier of flanges and pipe fittings. We have mature CBAM forms for flanges and pipe fittings that have been verified by other European customers.

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve