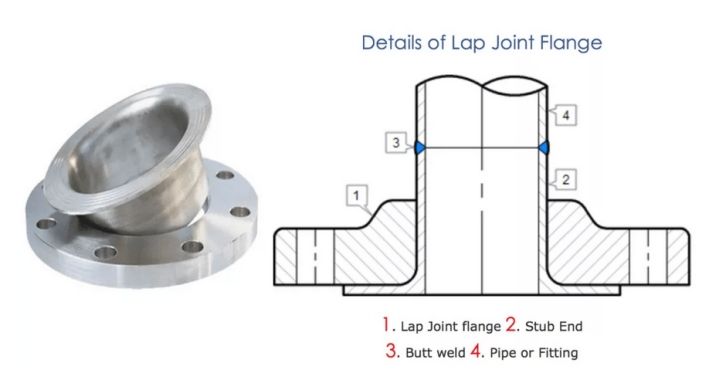

A loose flange, also known as a "lap joint flange" or "lap flange", is a type of flange that requires a matching stub end of a loose flange to connect. The purpose of using a loose flange is generally to save materials, and its structure is divided into two parts. Loose flanges are used on low-pressure pipelines, the working pressure is PN10 or CLASS150, and the stub end are always made of the same material as the pipeline to save materials.

The main advantage of the loose flange is that the flange can be rotated during installation to prevent the bolt holes from being misaligned, which is more convenient for workers to install.

How to use the loose flange:

Use flanges, steel rings, etc. to put the flange on the pipe end, and the flange can move on the pipe end. The steel ring or flange is the sealing surface, and the function of the flange is to compress them. It can be seen that the plate type loose flange is not in contact with the medium due to being blocked by the steel ring or flange. Because the flange is movable, it is not directly connected to the pipeline.

There are many types of sealing surfaces of loose flange flanges. Generally, there are convex surface, concave surface, concave-convex surface, tenon and groove surface, full plane and ring connection surface. The loose flange has simple structure, small volume, tightness and reliability, convenient operation and maintenance, pressure resistance and corrosion resistance.

Loose flanges are widely used in petroleum, chemical, food, dairy, pharmaceutical, machinery manufacturing, sewage treatment, municipal water supply pipelines, fire pipelines and other industries. For dimensions, please refer to eathu lapped joint flanges.