Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

Inquiry now

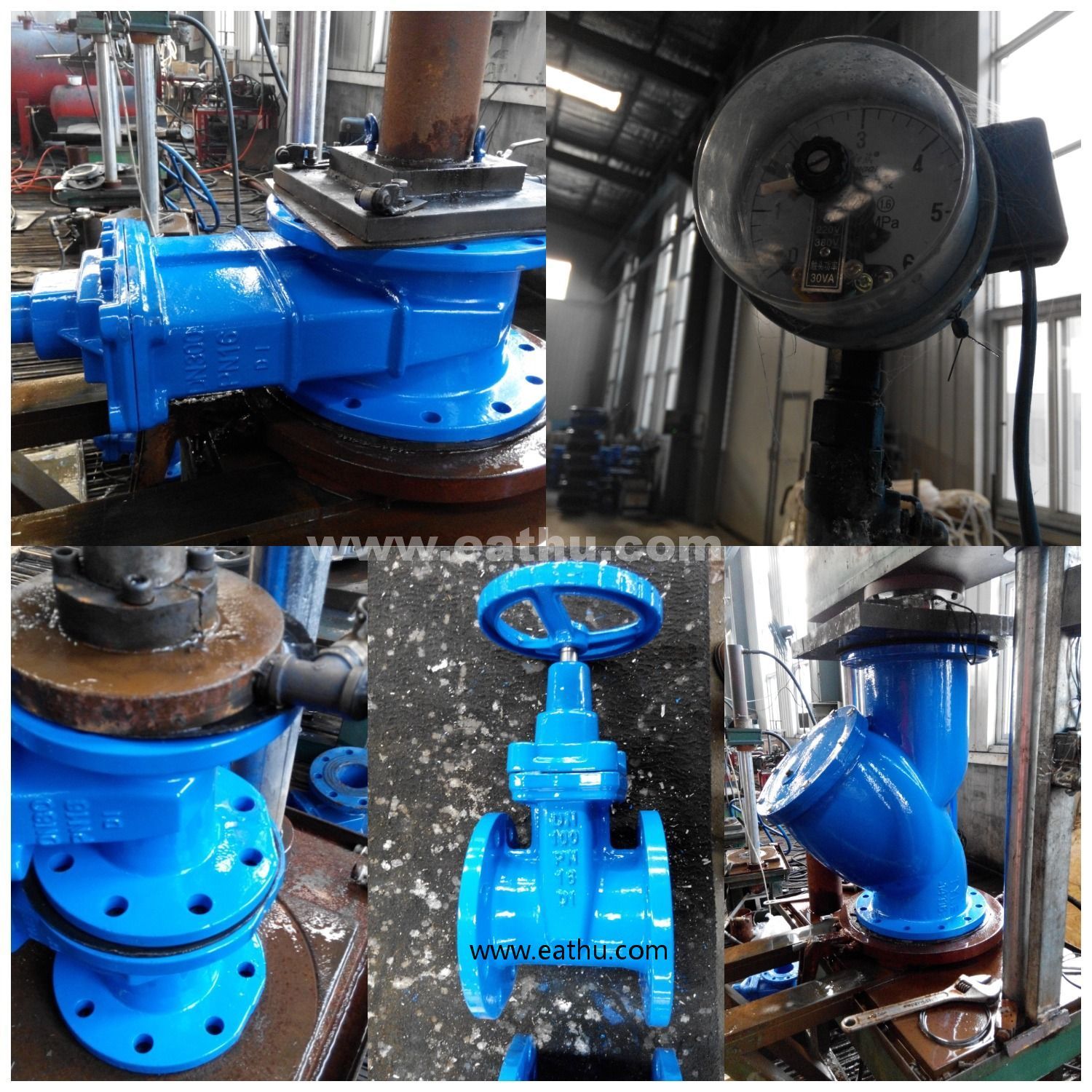

The gate valve opening and closing part is the valve gate, and the movement direction of the gate plate is perpendicular to the fluid direction. The gate valve can only be fully opened or fully closed, and cannot be used for adjustment and throttling. The gate has two sealing surfaces. Usually the two sealing surfaces of the valve plate form a wedge. The wedge angle varies with valve parameters, usually 50, and 2°52 when the medium temperature is not high. The gate of the wedge gate valve can be made into a whole, called a rigid gate; it can also be made into a gate that can produce slight deformation to improve its manufacturability and make up for the deviation of the sealing surface angle during the processing. The plate is called an elastic gate. When the gate valve is closed, the sealing surface can only rely on the medium pressure to seal, that is, rely on the medium pressure to press the sealing surface of the gate to the valve seat on the other side to ensure the sealing of the sealing surface, which is self-sealing. Most gate valves use forced sealing, that is, when the valve is closed, the gate must be forced against the seat by external force to ensure the sealing performance of the sealing surface.

The gate of the gate valve moves linearly along with the valve stem, which is called a lifting stem gate valve, also called a rising stem gate valve. Usually there is a trapezoidal thread on the lifting rod, through the nut of the valve and the guide groove on the valve body, the rotary motion is changed into linear motion, that is, the operating torque is turned into operating thrust. When the valve is opened, when the lifting height of the gate is equal to 1:1 times the valve diameter, the fluid passage is completely unblocked, but this position cannot be monitored during operation. In actual use, the apex of the valve stem is used as the mark, that is, the unmovable position, as its fully open position. In order to consider the lock-up phenomenon due to temperature changes, it is usually opened to the apex position, and then back 1/2 to 1 turn, as the fully open valve position. Therefore, the fully open position of the valve is determined by the position of the gate, that is, the stroke. In some gate valves, the stem nut is set on the gate, and the rotation of the handwheel drives the rotation of the valve stem to lift the gate. This kind of valve is called a rotating stem gate valve or a dark stem gate valve.

The type of gate width can be divided into wedge gate valve and parallel gate valve according to the sealing surface configuration. Wedge gate valve can be divided into: single gate, double gate and elastic gate; parallel gate valve It can be divided into single gate type and double gate type. Divided according to the thread position of the valve stem, it can be divided into two types: open stem gate valve and dark stem gate valve. The installation and maintenance of the gate valve should pay attention to the following items: The handwheel, handle and transmission mechanism are not allowed to be used for lifting, and collisions are strictly prohibited. The double gate valve should be installed vertically, that is, the valve stem is in the vertical position and the handwheel is at the top. The gate valve with bypass valve should be opened before opening to balance the pressure difference between the inlet and outlet and reduce the opening force. The gate valve with transmission mechanism should be installed according to the product manual. If the valve is frequently opened and closed, lubricate at least once a month.

Advantages of gate valve

The fluid resistance is small, and the sealing surface is less brushed and corroded by the medium. It is easier to open and close. The medium flow direction is not restricted, does not disturb the flow, and does not reduce the pressure. The shape is simple, the length of the structure is short, the manufacturing process is good, and the scope of application is wide.

Disadvantages of gate valve

It is easy to cause erosion and scratches between the sealing surfaces, and maintenance is difficult. The external size is large, the opening requires a certain amount of space, and the opening and closing time is long. The structure is more complicated.

Electric gate valve

It is a kind of linear motion valve. It is matched with the Z-type multi-turn actuator. There are switch type and intelligent type. This valve is simple to operate and is a common open-close valve, which uses the up and down work of the gate to switch on and off the fluid medium in the pipeline. It is widely used in electric power, metallurgy, petroleum, chemical, paper, sewage treatment and other sectors.

Pneumatic gate valve

It is a double-layer cylinder with a pneumatic actuator, and is equipped with a buffer mechanism and a manual and protective mechanism. The valve adopts a double-layer cylinder structure, and its lifting force is doubled compared with a single-cylinder pneumatic gate valve. This fundamentally solves the problem that certain valve bodies of the single-cylinder pneumatic gate valve cannot be opened due to wedging. Moreover, because the valve has a buffer mechanism, it can effectively slow down and lighten the wear of the valve plate car sealing surface and valve body sealing surface due to the downward impact of the piston when the valve is closed. At the same time, it can also avoid the phenomenon of gate jamming.

Eathu contact information:

info@eathu.com

whatsapp/skype/mob: +86 132 1015 3062

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88550858

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve