Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

Inquiry now

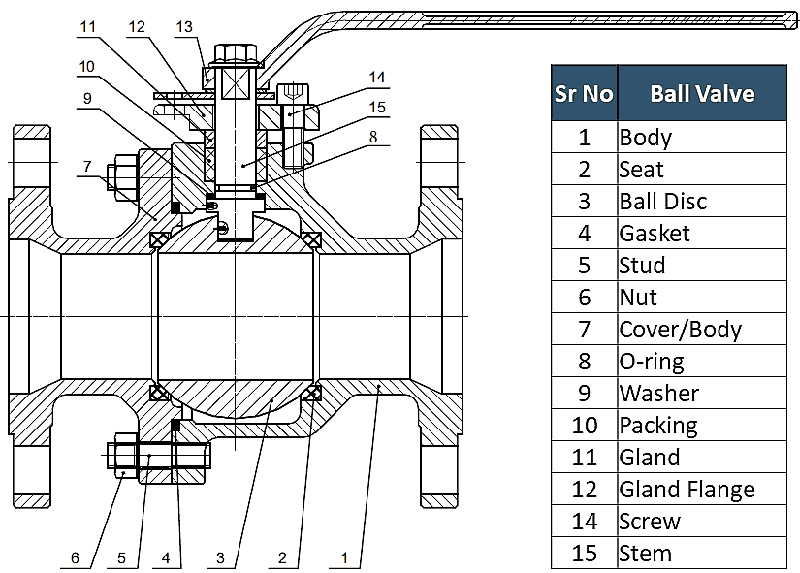

The major components of a ball valve include:

Valve body – A pressure vessel that contains the components needed to control or shut off the flow through a pipe. It is designed to connect two or more sections of pipe or tubing to each other.

Ball – A sphere with a flow path (hole or tunnel) through the center of it and a connection point for a shaft to rotate it.

Seats – Round donut-shaped discs that form a seal between the body and ball.

Stem – A shaft that connects the internal ball to the outside of the valve to facilitate rotation of the ball.

Packing – Flexible seals that fit around the shaft and prevent the media traveling through the valve from escaping externally.

Bonnet – The part of the valve body that houses the stem and packing.

Operator or Actuator – An external device designed to rotate the stem of the valve. This can be a lever, a gear, a motor-operated gear (electric actuator), or a pneumatic/hydraulic actuator.

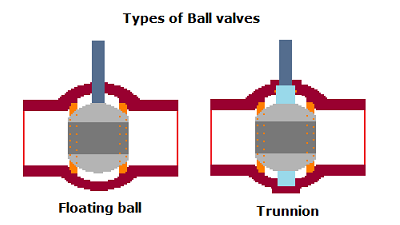

The most common design is the "floating ball design". The ball is suspended in the media and held in place by two sealing rings. Some high-quality valves have a "trunnion ball design". The ball is supported at the top and bottom to reduce the load on the valve seats.

Floating - The majority of ball valves have a floating ball. The ball is supported by the valve seats.

Trunnion - Valves with large diameters and high operating pressures (for example DN >100mm and 30 bar) have often a trunnion design. The ball is supported on the bottom and top to reduce the load on the seat rings. The operating torque is generally lower for trunnion valves.

The hole through the ball may have different profiles such as a full bore, reduced bore or V-shaped.

Reduced bore - Most ball valves have a reduced bore. As a result, the ball valve introduces friction losses in the system. These losses are still relatively small compared to other types of valves. One-piece ball valves are almost always reduced bore.

Full bore - Full bore valves have the same bore diameter as the pipe. The advantage is that there are no extra friction losses, and that the system is mechanically easier to clean (pigging). The downside is that the ball and the housing are bigger than a standard ball valve with reduced bore. The cost is therefore slightly higher, and for many applications this is not required.

V-shaped - The hole in the ball or the valve seat has a "V" shaped profile. As a result, the desired flow rate can be controlled more precisely by rotating the ball. By optimizing the profile, a linear flow characteristic can be approached.

What are the differences between floating ball valve & trunnion ball valve. There are major 5 points.

1.Appearance

The floating ball valve and the trunnion ball valve are easy to distinguish in appearance. If the valve body has a fixed shaft on the bottom, it must be the trunnion ball valve.

If the ball valve body has a device for injecting grease,it is basically a trunnion ball valve.However, if there is no injecting device,can we say it must be a floating ball valve? This is incorrect, because small size such as 2 "150LB trunnion ball valves are usually not filled with injecting device either.

2. Sealing surface

As the ball of the floating ball valve is floating, so under the pressure of the medium, the floating ball will move and against the downstream seat., so the seal of the floating ball valve belongs to the single-side seal.The ball of the trunnion ball valve cannot be moved, so the two sides of the trunnion ball valve both must be sealed.

Since the sealing principle is different, the requirements of the two ball valves on the sealing surface material are different, especially the sealing surface of the floating ball valve must be able to bear the pressure caused by the floating ball.

3. Working principle

The floating ball valve only has upper stem and the ball can have a slight displacement, so it is called floating ball valve.The trunnion ball valve ball has another stem at the bottom to fixed the position of the ball,so the ball can’t move.

The sealing of the floating ball valve is realized by the pressure of the medium, when the ball valve is closed, the floating ball is pressed against the sealing surface under the action of pressure to realize sealing.When the trunnion ball valve is closed, the ball does not produce displacement, but the floating seats will move and press against the ball under the action of the media pressure to realize sealing.

4. Application

The floating ball valve is suitable for medium and low pressure and usually has a small diameter.The trunnion ball valve can be used in high pressure conditions and the size can be up to 60 inches.

The trunnion ball valve is a kind of double-block-and-bleed(DBB) valve, while the floating ball valve only seal the downstream side. The trunnion ball valve can block both upstream and downstream media. And when the pressure in the middle cavity is greater than the seat spring force, the seat will be pushed open to release the pressure inside the chamber to ensure safety.

5.Characteristics

To the floating ball valves, the trunnion ball valves are usually used longer, has smaller size and easier to operate.

The trunnion ball valve also has the function of automatic release pressure, when the medium temperature in the valve rises and causes abnormal pressure rise, the trunnion ball valve can automatically release the pressure without a relief valve,This is very important to ensure the safety of industrial production.

Export Office: 21Floor, No.5 Nanhai Zhi Road,Qingdao, Shandong ,China

Work Shop: Beian Industrial zone, Qingdao,Shandong,China

+86 532 88256399

Martin

© 2020 Qingdao Fluido Industrial Co.,Ltd. All Rights Reserved. Qingdao fluido valve